Canning is something most newbies want to do but are intimidated by. Their imaginations go into overdrive and they worry about things breaking, blowing up, or any number of other calamities happening. There is a learning curve that can turn some people away, thinking it's too complicated for them. … [Read more...]

Unraveling the Mystery: Make Your Own Vinegar

Vinegar (a French word for "sour wine") is one of those things that is largely taken for granted. Once upon a time, vinegar was a 'must have' for any kitchen - and not just for cooking with. In fact, vinegar was used for all manner of cleaning, food preservation, and even used for medicinal … [Read more...]

Unraveling the Mystery: Making Jams and Jellies

It's berry season!! Here in Southeast Alaska, we have three different berries that are prevalent: blueberries, huckleberries, and salmonberries. Three years ago, I taught myself how to make jams and jellies (yay for YouTube videos!) and we have not purchased so much as a single jar of either from … [Read more...]

Unraveling the Mystery: Making Cheese

CHEESE!! Both Mister Dreamer and I absolutely love cheese, all different kinds. I have written before about this wonderful food that can be stored for a longer time than most foods. It is one of the few ways we can ‘preserve’ dairy. As many of the long time followers know, we love to smoke … [Read more...]

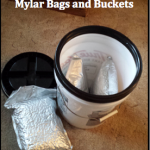

Unraveling The Mystery: Using Mylar Bags and Buckets

Most people know about the use of Mylar bags, oxygen absorbers, and buckets as a way of preserving and storing food for the long term. What they don’t know is how and why it works! There are also a lot of misconceptions and untrue beliefs that surround this particular method of food preservation. … [Read more...]

Unraveling the Mystery: Making Jerky

I’ve been saving this one for awhile. I expect it may get a good amount of attention because, let’s face it, jerky is pretty much one of the best things on the planet, right? (Vegetarians and Vegans excluded, of course). Well, it also happens to be one of the easiest things to make yourself! It is … [Read more...]

Unraveling the Mystery: Water Bath Canning

Water bath canning is a fantastic and incredibly easy way to get into preserving and packaging your own food. I consider it the ‘gateway’ to pressure canning as it is less intimidating and like I said, incredibly easy! It requires less ‘specialized’ equipment than pressure canning does, too. Chances … [Read more...]